1. Why do you design plywood glass epoxy construction and not say balsa core or foam sandwich boats ?

As I design in the first place boats for amateurs construction, it is the simplest way to go.

A. TOOLS

Most first time boat builders will have already the necessary tools in there workshop.

The equipment for infusion or vacuum construction can cost you more as the plywood for a wood/Epoxy boat.

B. QUALITY CONTROLL

If you build in a foam or balsa core system you have to learn how to work with these materials. It is difficult to check the quality of the work. In contrast the wood/epoxy system can be checked by eye sight. For example a bulkhead to planking connection or air inclusion in a glass cloth lay up.

C. TIME

Besides the strong back which you have to build for bigger boats, every part you make will be part of the boat. For the smaller boats you need not even a strong back. In a foam sandwich construction you have to build first a sort of a mold over which the foam/balsa whatever parts are placed (temporary fastened) to start with. After finishing you throw them away. A waste of time and money.

To finish a plywood hull is easy and fast, because the plywood has already a good surfaces. In most cases a sandwich construction will need a lot of sanding. I never forget an article in the German “Multi hull bote” magazine where a builder reported that he has finished his first hull of his 12 m foam sandwich catamaran after one year. One of our builders built his PELICAN (11m long) in precise one year.

D. COSTS

Here the advantage of the plywood epoxy system is clear. Depending on the country where you life the cost factor will be between 1 : 4 till 1 : 6 in favor of the wood/glass/epoxy system. Check your supplier and see for your self.

E. MAINTENANCE

Wood/glass/epoxy constructions do not get weak as is known with polyester and sandwich multi hulls.

Wood/glass epoxy boats do not absorb water as is known with polyester boats.

Osmosis is a no no with Epoxy.

Wood/glass/epoxy constructions do not get weak as is known with polyester and sandwich boats.

After 11 years of use, many thousands mails of sailing and permanent living on our PELICAN the original paint was still on the boat. The paint was a bit dull in some places that was it.

F. RE- SALE VALUE

Plywood boats got a bad name before Epoxy was used. Many plywood boats rotting away from the inside because of bad ventilation. On the corners water entered the wood fiber capillary structure and the boat was rotting away.

Modern wood/glass/Epoxy boats avoid all this. Resulting in a long lasting and low maintenance boat. But, a lot of persons have still the picture of the old plywood boats. The are principal plywood/glass/Epoxy sandwich constructions.

Here in France new plywood/glass sandwich boats are built, mono and multi hulls. It is a question of education. These boats are sold as good as boats designed for any other construction system.

So yes perhaps you have to sell your boat for a lower price as would be a polyester catamaran for example. So what, your boat was built much quicker and cheaper as the other boat, so you can afford to sell it a bit cheaper.

You will make in the end a profit or at least get your money back. We sold our PELICAN in two weeks time and made about 80 % profit. If you sell your production boat you loose money anyway. So where is the problem.

As I design in the first place boats for amateurs construction, it is the simplest way to go.

A. TOOLS

Most first time boat builders will have already the necessary tools in there workshop.

The equipment for infusion or vacuum construction can cost you more as the plywood for a wood/Epoxy boat.

B. QUALITY CONTROLL

If you build in a foam or balsa core system you have to learn how to work with these materials. It is difficult to check the quality of the work. In contrast the wood/epoxy system can be checked by eye sight. For example a bulkhead to planking connection or air inclusion in a glass cloth lay up.

C. TIME

Besides the strong back which you have to build for bigger boats, every part you make will be part of the boat. For the smaller boats you need not even a strong back. In a foam sandwich construction you have to build first a sort of a mold over which the foam/balsa whatever parts are placed (temporary fastened) to start with. After finishing you throw them away. A waste of time and money.

To finish a plywood hull is easy and fast, because the plywood has already a good surfaces. In most cases a sandwich construction will need a lot of sanding. I never forget an article in the German “Multi hull bote” magazine where a builder reported that he has finished his first hull of his 12 m foam sandwich catamaran after one year. One of our builders built his PELICAN (11m long) in precise one year.

D. COSTS

Here the advantage of the plywood epoxy system is clear. Depending on the country where you life the cost factor will be between 1 : 4 till 1 : 6 in favor of the wood/glass/epoxy system. Check your supplier and see for your self.

E. MAINTENANCE

Wood/glass/epoxy constructions do not get weak as is known with polyester and sandwich multi hulls.

Wood/glass epoxy boats do not absorb water as is known with polyester boats.

Osmosis is a no no with Epoxy.

Wood/glass/epoxy constructions do not get weak as is known with polyester and sandwich boats.

After 11 years of use, many thousands mails of sailing and permanent living on our PELICAN the original paint was still on the boat. The paint was a bit dull in some places that was it.

F. RE- SALE VALUE

Plywood boats got a bad name before Epoxy was used. Many plywood boats rotting away from the inside because of bad ventilation. On the corners water entered the wood fiber capillary structure and the boat was rotting away.

Modern wood/glass/Epoxy boats avoid all this. Resulting in a long lasting and low maintenance boat. But, a lot of persons have still the picture of the old plywood boats. The are principal plywood/glass/Epoxy sandwich constructions.

Here in France new plywood/glass sandwich boats are built, mono and multi hulls. It is a question of education. These boats are sold as good as boats designed for any other construction system.

So yes perhaps you have to sell your boat for a lower price as would be a polyester catamaran for example. So what, your boat was built much quicker and cheaper as the other boat, so you can afford to sell it a bit cheaper.

You will make in the end a profit or at least get your money back. We sold our PELICAN in two weeks time and made about 80 % profit. If you sell your production boat you loose money anyway. So where is the problem.

FAQ

Here some of the answers of often asked questions. The question/ answer section has no structure, but I hope it will help you. I will add subjects in irregular intervals prior to your questions in the future.

1. Why do you design plywood glass epoxy construction and not say balsa core or foam sandwich boats ?

A. TOOLS

B. QUALITY CONTROL

C. TIME

D. COSTS

E. MAINTENANCE

F. RE- SALE VALUE

2. BOAT DESING QUESTIONS

Why do you design mostly chine hull boats ?

Do need a-symmetrical hulls boards or keels ?

Is coming about difficult with a-symmetrical cats ?

Do your boats hobby horse ?

Bridge deck clearance and standing height

Why do you not have deck houses on your catamarans ?

How work biplane (parallel) rigs ?

1. Why do you design plywood glass epoxy construction and not say balsa core or foam sandwich boats ?

A. TOOLS

B. QUALITY CONTROL

C. TIME

D. COSTS

E. MAINTENANCE

F. RE- SALE VALUE

2. BOAT DESING QUESTIONS

Why do you design mostly chine hull boats ?

Do need a-symmetrical hulls boards or keels ?

Is coming about difficult with a-symmetrical cats ?

Do your boats hobby horse ?

Bridge deck clearance and standing height

Why do you not have deck houses on your catamarans ?

How work biplane (parallel) rigs ?

2. BOAT DESING QUESTIONS

Why do you design mostly chine hull boats ?

Plywood is the material to design catamarans with chine cross section hulls. There is nothing wrong to have hulls with chines. Look on modern ultra light ocean racing monos. Besides on the bows the have rounded of sharpie sections.

I do the same. Most of my designs have a round under water cross section at the bows which are veered out to a sharp chine future on. The sharp chine abaft helps on combination with the anti vortex panels to sail to windward, often better as boats with keels or dagger boards By the way, because of my background in aerodynamic engineering I was the first to describe the working principle of these panels, chine runners, winglets or how you like to call them. We use the anti vortex panels on all our trapezoid cross section catamaran designs. Our Pelican is pointing as high as a very good mono hull and general better as good catamarans with dagger boards or low aspect ratio keels. Of course there other design factors which make a boat go to wind wards. Like free board an superstructure like deck houses etc.

Do need a-symmetrical hulls boards or keels ?

You can look at a-symmetrical hulls (like any other hull) as wings standing vertical in the water.

The aircraft wings upper surface is “bent” and the lower “flat”. So a wing cross section is a-symmetrical.

(If this is all new for you go to this article where I explain the working of boards and rudder including the wing theory.)

The generated lift depends on the angle of attack of the wing. The bigger the angle, till a given angle, the lift increases (till a given angle then the wing stalls, beware).

The angle of attack is the leeway angle a hull needs to generate enough force to use the sail force to generate a forward motion of the boat.

Two lift forces ( lift coefficient of wing sections) NACA 64A410 as example for an a-symmetrical wing section or a-symmetrical hull.

Angle of attack 4 ° lift coefficient 0,8.

NACA 65-018 as example for a symmetrical wing section or hull.

Angle of attack 4° , lift coefficient 0,4.

This is the explanation why a-symmetrical hulls need no other means to sail very good to windward. The argument that when the boat is on even keel the two hulls will equalize the windward effect is nonsense. Because you hear never this argument for symmetrical hulls.

Also catamarans sail with a slant to lee wards ( +/- 3°). This is sufficient for both types of hulls.

A bit more concerning a-symmetrical hulls. Technical it is impractical to design wide a-symmetrical hulls. Typical the length to beam ratio can be not lower as 1 : 14. This means very slender hulls with not a lot of inside space and a bigger whetted area as symmetrical hulls. So these boats are not good load carriers. The whetted surface is bigger, so the boats are slower in low wind speeds. When the wind increases the boats gets faster and the running water resistance decreases very fast. Which in turn gives more speed. Our extreme a-symmetrical cat DUO 425 is even faster as wind surfers. One of the best effects which is appreciated on bigger sea going a-symmetrical boats is that the compensate for yaw in following and diagonal waves. This means almost no tendency to broach. The sail like on rails.

Is coming about difficult with a-symmetrical cats ?

You know how to drive your car trough a corner ? Then you can “drive” an a-symmetrical cat trough the wind. You drive your car slow trough a corner anything is fine, you do it with a jerk on the steering wheel the car turns over. An a-symmetrical cat will go straight on when you do this on the helm. When you do it slow the boat will nicely go trough the wind. My experience enables me to design asymmetrical cats which come about as any good symmetrical boat. Read the inputs from KD 650 owners.

Do your boats hobby horse ?

No, only longitudinal symmetrical hulls hobby horse. Typical some of the V cross section hull catamarans do so. Why is this? Pull on a spring with a weight. The spring will go on for a long time till it stops swinging. Have a shock absorber in the spring and she will stop after a short time. Hulls which are designed wider towards the transom (more volume aft as front) will also compensate and not hobby horse.

By the way, keep the “ends” of the boat light. This makes the boat quicker to recover from longitudinal swinging special on the bow. This is a reason my boats are empty (have a collisions bulkhead) at the bow.

Bridge deck clearance and standing height

There is a direct relation between bridge deck clearance and standing height on the bridge deck.

The minimum bridge deck clearance should be 6 % of the water line length.

For example waterline length 8,65m, 6% = 0,51m. Now you want 1,85m standing height in the saloon. This boils down to a height above the water of 2,36m. For a boat length of 8,65 m this is clearly to high. To realize standing height the boat has to be 12 m long.

If a boat with a waterline length of 8,65 is build this high it can not sail to windward any more if the sails are shortened in heavy wind and big waves. Because the projected side area of the boat in relation to the sail area is to big. The boat is un-seaworthy. Or you have to use a big engine to sail you free. It becomes a motor sailor. This is a reason why a lot of production multi hulls have this big engines.

But there is more to bridge deck clearance. When you observe how a boat moves trough, over a wave you can see that the wave first rises on the bow till the boat reacts and lift its bow. A catamaran on which the bridge deck is going till the bow or almost to the bow will be hit by the wave and slam. This is way on all my catamarans the bridge deck begins so far back from the bow. This costs deck and inside space, but is a lot safer.

Why do you design mostly chine hull boats ?

Plywood is the material to design catamarans with chine cross section hulls. There is nothing wrong to have hulls with chines. Look on modern ultra light ocean racing monos. Besides on the bows the have rounded of sharpie sections.

I do the same. Most of my designs have a round under water cross section at the bows which are veered out to a sharp chine future on. The sharp chine abaft helps on combination with the anti vortex panels to sail to windward, often better as boats with keels or dagger boards By the way, because of my background in aerodynamic engineering I was the first to describe the working principle of these panels, chine runners, winglets or how you like to call them. We use the anti vortex panels on all our trapezoid cross section catamaran designs. Our Pelican is pointing as high as a very good mono hull and general better as good catamarans with dagger boards or low aspect ratio keels. Of course there other design factors which make a boat go to wind wards. Like free board an superstructure like deck houses etc.

Do need a-symmetrical hulls boards or keels ?

You can look at a-symmetrical hulls (like any other hull) as wings standing vertical in the water.

The aircraft wings upper surface is “bent” and the lower “flat”. So a wing cross section is a-symmetrical.

(If this is all new for you go to this article where I explain the working of boards and rudder including the wing theory.)

The generated lift depends on the angle of attack of the wing. The bigger the angle, till a given angle, the lift increases (till a given angle then the wing stalls, beware).

The angle of attack is the leeway angle a hull needs to generate enough force to use the sail force to generate a forward motion of the boat.

Two lift forces ( lift coefficient of wing sections) NACA 64A410 as example for an a-symmetrical wing section or a-symmetrical hull.

Angle of attack 4 ° lift coefficient 0,8.

NACA 65-018 as example for a symmetrical wing section or hull.

Angle of attack 4° , lift coefficient 0,4.

This is the explanation why a-symmetrical hulls need no other means to sail very good to windward. The argument that when the boat is on even keel the two hulls will equalize the windward effect is nonsense. Because you hear never this argument for symmetrical hulls.

Also catamarans sail with a slant to lee wards ( +/- 3°). This is sufficient for both types of hulls.

A bit more concerning a-symmetrical hulls. Technical it is impractical to design wide a-symmetrical hulls. Typical the length to beam ratio can be not lower as 1 : 14. This means very slender hulls with not a lot of inside space and a bigger whetted area as symmetrical hulls. So these boats are not good load carriers. The whetted surface is bigger, so the boats are slower in low wind speeds. When the wind increases the boats gets faster and the running water resistance decreases very fast. Which in turn gives more speed. Our extreme a-symmetrical cat DUO 425 is even faster as wind surfers. One of the best effects which is appreciated on bigger sea going a-symmetrical boats is that the compensate for yaw in following and diagonal waves. This means almost no tendency to broach. The sail like on rails.

Is coming about difficult with a-symmetrical cats ?

You know how to drive your car trough a corner ? Then you can “drive” an a-symmetrical cat trough the wind. You drive your car slow trough a corner anything is fine, you do it with a jerk on the steering wheel the car turns over. An a-symmetrical cat will go straight on when you do this on the helm. When you do it slow the boat will nicely go trough the wind. My experience enables me to design asymmetrical cats which come about as any good symmetrical boat. Read the inputs from KD 650 owners.

Do your boats hobby horse ?

No, only longitudinal symmetrical hulls hobby horse. Typical some of the V cross section hull catamarans do so. Why is this? Pull on a spring with a weight. The spring will go on for a long time till it stops swinging. Have a shock absorber in the spring and she will stop after a short time. Hulls which are designed wider towards the transom (more volume aft as front) will also compensate and not hobby horse.

By the way, keep the “ends” of the boat light. This makes the boat quicker to recover from longitudinal swinging special on the bow. This is a reason my boats are empty (have a collisions bulkhead) at the bow.

Bridge deck clearance and standing height

There is a direct relation between bridge deck clearance and standing height on the bridge deck.

The minimum bridge deck clearance should be 6 % of the water line length.

For example waterline length 8,65m, 6% = 0,51m. Now you want 1,85m standing height in the saloon. This boils down to a height above the water of 2,36m. For a boat length of 8,65 m this is clearly to high. To realize standing height the boat has to be 12 m long.

If a boat with a waterline length of 8,65 is build this high it can not sail to windward any more if the sails are shortened in heavy wind and big waves. Because the projected side area of the boat in relation to the sail area is to big. The boat is un-seaworthy. Or you have to use a big engine to sail you free. It becomes a motor sailor. This is a reason why a lot of production multi hulls have this big engines.

But there is more to bridge deck clearance. When you observe how a boat moves trough, over a wave you can see that the wave first rises on the bow till the boat reacts and lift its bow. A catamaran on which the bridge deck is going till the bow or almost to the bow will be hit by the wave and slam. This is way on all my catamarans the bridge deck begins so far back from the bow. This costs deck and inside space, but is a lot safer.

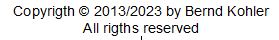

Why do you not have deck houses on your catamarans ?

Almost all of my cruiser catamarans are “flat” deck constructions (B). I am a big believer in Dick Newicks KISS (keep it stupid simple) philosophy. Why have a deck house or coffer superstructure (A) when a flat deck design is so much more logical. Both cross sections show a cat with the same cabin height, beam and bridge deck clearance.

Almost all of my cruiser catamarans are “flat” deck constructions (B). I am a big believer in Dick Newicks KISS (keep it stupid simple) philosophy. Why have a deck house or coffer superstructure (A) when a flat deck design is so much more logical. Both cross sections show a cat with the same cabin height, beam and bridge deck clearance.

1. Because of the more or less vertical side of the deck house of type A the air resistance is high. If such a boat is sailed with shortened sails in heavy weather, the boat can not sail to windward as good as a flat deck boat. Type B will always sail better and faster as A. Exception, before the wind, but then anything sails, even a bale of hay.

2. The deck to deck house connection of A will be the weak spot of this boat. Not only when walking on the deck, more worse when a wave will hit there. This is the weakest area for damage.

3. The strain on the chain plate of the mast shouts introduces a high stress load in this are. The deck to deck house are wants to fold inwards (see red line). The same load on type B is more even spread. By this the whole construction can be lighter.

4. Often when a boat starts to leak it is in this area.

5. The construction of version A is more difficult as B.

6. To build type A will take more time as type B.

7. The boat will be more heavy as type B.

8. Walking on the often small decks of type A is dangerous in heavy weather. Where on type B you have the whole deck for save walking.

So why you see not more “flat” deck catamarans ?

Very simple, you can not make the deck roach to big on type B to gain more height in the center room (saloon). But it is easy to make the deck house higher for more head room. The result will be a boat with a lot of room but no good sailing behavior.

See also Bridge deck clearance and standing height.

2. The deck to deck house connection of A will be the weak spot of this boat. Not only when walking on the deck, more worse when a wave will hit there. This is the weakest area for damage.

3. The strain on the chain plate of the mast shouts introduces a high stress load in this are. The deck to deck house are wants to fold inwards (see red line). The same load on type B is more even spread. By this the whole construction can be lighter.

4. Often when a boat starts to leak it is in this area.

5. The construction of version A is more difficult as B.

6. To build type A will take more time as type B.

7. The boat will be more heavy as type B.

8. Walking on the often small decks of type A is dangerous in heavy weather. Where on type B you have the whole deck for save walking.

So why you see not more “flat” deck catamarans ?

Very simple, you can not make the deck roach to big on type B to gain more height in the center room (saloon). But it is easy to make the deck house higher for more head room. The result will be a boat with a lot of room but no good sailing behavior.

See also Bridge deck clearance and standing height.

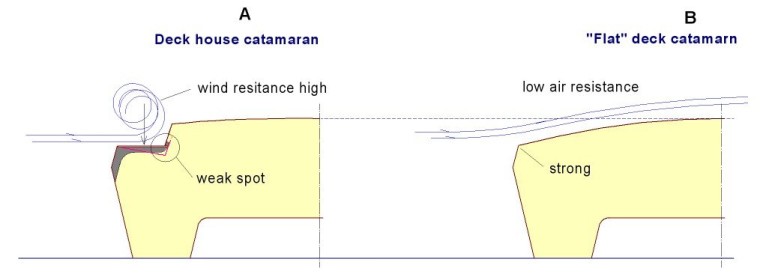

How work biplane (parallel) rigs ?

Our DUO 425 was the first beach catamaran with a parallel rig. After some theoretical work I decided to give it a try. In this time (1984) you could get a windsurf rig for about 150 Dutch Guilders.

I will try to explain the advantages of this rig without getting to theoretical.

Our DUO 425 was the first beach catamaran with a parallel rig. After some theoretical work I decided to give it a try. In this time (1984) you could get a windsurf rig for about 150 Dutch Guilders.

I will try to explain the advantages of this rig without getting to theoretical.

The biggest advantage is more sail area in respect to a sloop rig (jib and main sail) with a lower center of effort.

N.B. Schooner or ketch rigs have the problem that the Schooner sail (besan) sail is in the „dirty air“ from the forward sail in a course to windward. The have there merits on mono hulls which sail in an other speed range.

Result: The boat can be sailed in higher wind speeds as a sloop rig. Which means more speed.

A parallel rig generates also more power as a sloop…..

First take a look at the drawing.

VT is at 90 degree to the boat. The projection of the wind (blue lines) is not correct of course but to explain the effects on the sail this is more convenient.

The wind ward sail is set at a bigger angle as the lee wards sail. The conservation of mass is a fundamental concept of physics . When a given amount of air enters the area between the sails, the same amount has to leave the gab. Though the narrowing between the sails the velocity has to increase. As a result the „suction“ power on the wind ward sail increases and the „pushing“ power on the lee sail increases. As a consequence the total force of the sails increases which means more speed.

How fast can you go ? This depends on how far forward the apparent wind hits the sail. When the sail on the leading edge fells in, power is lost. This will be the absolute limit. In fact the sails lose power before because the angle of attack of the sail gets to shallow for optimum lift (CL) generation.

A lot is written about blanked out leeward sails. If the weight to sail area ratio (power ratio) is to high. With other words, the boat is to heavy, forget to use a parallel rig.

The triangulations shown from left to right, from a slow till a fast boat. By this it is clear that the biplane rigged boat has to be an easy driven light boat to make full use of the effect.

N.B. Schooner or ketch rigs have the problem that the Schooner sail (besan) sail is in the „dirty air“ from the forward sail in a course to windward. The have there merits on mono hulls which sail in an other speed range.

Result: The boat can be sailed in higher wind speeds as a sloop rig. Which means more speed.

A parallel rig generates also more power as a sloop…..

First take a look at the drawing.

VT is at 90 degree to the boat. The projection of the wind (blue lines) is not correct of course but to explain the effects on the sail this is more convenient.

The wind ward sail is set at a bigger angle as the lee wards sail. The conservation of mass is a fundamental concept of physics . When a given amount of air enters the area between the sails, the same amount has to leave the gab. Though the narrowing between the sails the velocity has to increase. As a result the „suction“ power on the wind ward sail increases and the „pushing“ power on the lee sail increases. As a consequence the total force of the sails increases which means more speed.

How fast can you go ? This depends on how far forward the apparent wind hits the sail. When the sail on the leading edge fells in, power is lost. This will be the absolute limit. In fact the sails lose power before because the angle of attack of the sail gets to shallow for optimum lift (CL) generation.

A lot is written about blanked out leeward sails. If the weight to sail area ratio (power ratio) is to high. With other words, the boat is to heavy, forget to use a parallel rig.

The triangulations shown from left to right, from a slow till a fast boat. By this it is clear that the biplane rigged boat has to be an easy driven light boat to make full use of the effect.

Now how to sail such a boat?

The biplane (parallel) rig, obviously can only work when the boat is sailing to windward.

Otherwise the leeward sail is out of the air stream and will not work.

If all criteria are right i.e. the boat is light as our DUO 425 and 800 are. Presume a medium wind force of 3 to 5.

For example when you sail on a half wind course to the wind.

Observe the greater angle of the windward sail

Set the lee sail till it draws. Now play with the wind ward sail. The boat will reach its optimum speed when the angle is slightly bigger in respect to the forward movement of the boat. Look at the windward sail as the jib of the boat.

In a force 4 wind this works also when the wind is coming in about till 120 ° from the center line of the boat.

This is all to it. Remember, the „jib“ changes depending to your course.

Wing to wing sailing is not interesting with a fast parallel rig boat. Because the loss (air resistance) will become to high (about 33 % loss). It is better to tack. O.K. the distance is bigger, but because of the much higher speed when tacking as an end result you will be faster at your destination.

There are more successful parallel ( biplane ) rig catamarans. Here only an other example.

The Aquitaine from Yves Parlier. He set the 24 hour record to 586,5 miles with an average speed of 24,39 knots.

The biplane (parallel) rig, obviously can only work when the boat is sailing to windward.

Otherwise the leeward sail is out of the air stream and will not work.

If all criteria are right i.e. the boat is light as our DUO 425 and 800 are. Presume a medium wind force of 3 to 5.

For example when you sail on a half wind course to the wind.

Observe the greater angle of the windward sail

Set the lee sail till it draws. Now play with the wind ward sail. The boat will reach its optimum speed when the angle is slightly bigger in respect to the forward movement of the boat. Look at the windward sail as the jib of the boat.

In a force 4 wind this works also when the wind is coming in about till 120 ° from the center line of the boat.

This is all to it. Remember, the „jib“ changes depending to your course.

Wing to wing sailing is not interesting with a fast parallel rig boat. Because the loss (air resistance) will become to high (about 33 % loss). It is better to tack. O.K. the distance is bigger, but because of the much higher speed when tacking as an end result you will be faster at your destination.

There are more successful parallel ( biplane ) rig catamarans. Here only an other example.

The Aquitaine from Yves Parlier. He set the 24 hour record to 586,5 miles with an average speed of 24,39 knots.