KD 1000

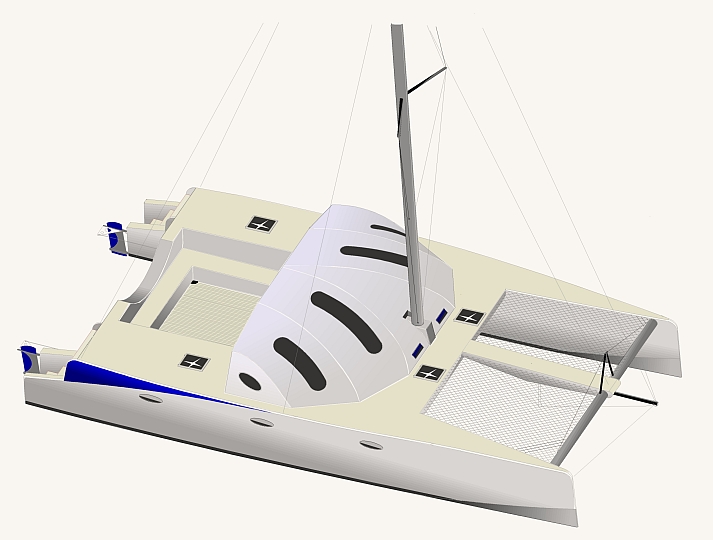

Here the result of a lot of research and listening to my customers, the KD 1000. A go anywhere on the world catamaran. As all my designs the boat is a plywood/glass/Epoxy composite construction. The most cost efficient system for a light weight construction. Ideal for amateur construction. No new trade to learn. Everybody who can work with a saw and a screwdriver can build the boat.

The hulls have a multi chine cross section with rounded side panels. Construction time about 400 hours per hull. The coach roof is a modified geodetic construction. The panels are bend and glued over templates. The roof has 3 layers of 4 mm plywood. Easy to bent and immense strong after the Epoxy is cured. The roof is finished with glass clothes. Some inside stringers are added at the corners at last. The quickest way to built a coach roof. It will safe you about 70% of building time in respect to any other construction systems. As with any bigger boat. Much time can be spend for the inside, like benches tables kitchen gear etc. So, I have stopped to give time for construction approximation.

The hulls have a multi chine cross section with rounded side panels. Construction time about 400 hours per hull. The coach roof is a modified geodetic construction. The panels are bend and glued over templates. The roof has 3 layers of 4 mm plywood. Easy to bent and immense strong after the Epoxy is cured. The roof is finished with glass clothes. Some inside stringers are added at the corners at last. The quickest way to built a coach roof. It will safe you about 70% of building time in respect to any other construction systems. As with any bigger boat. Much time can be spend for the inside, like benches tables kitchen gear etc. So, I have stopped to give time for construction approximation.

SPECIFICATION

L.o.a. 10,00 m ex. rudder

Beam c/c 5,00 m

Beam 6,22 m

Draft hulls loaded 0,39 m

Draft dagger board 1,70 m

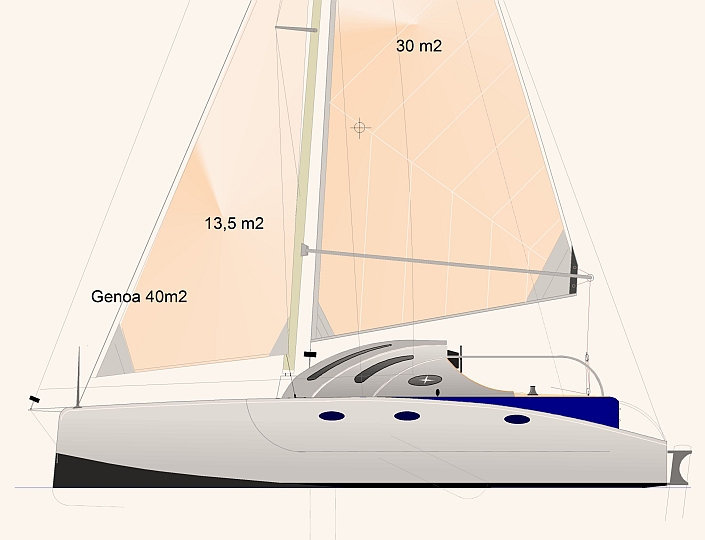

Main sail 30,00 m2

Jib 13,50 m2

Genoa 40,00 m2

Weight empty 2000 kg

Weight max.(CWL) 4200 kg

Engine: outboard 2x 10 hp

Construction time approx. 2000 hours*

* will be different for ever builder

L.o.a. 10,00 m ex. rudder

Beam c/c 5,00 m

Beam 6,22 m

Draft hulls loaded 0,39 m

Draft dagger board 1,70 m

Main sail 30,00 m2

Jib 13,50 m2

Genoa 40,00 m2

Weight empty 2000 kg

Weight max.(CWL) 4200 kg

Engine: outboard 2x 10 hp

Construction time approx. 2000 hours*

* will be different for ever builder

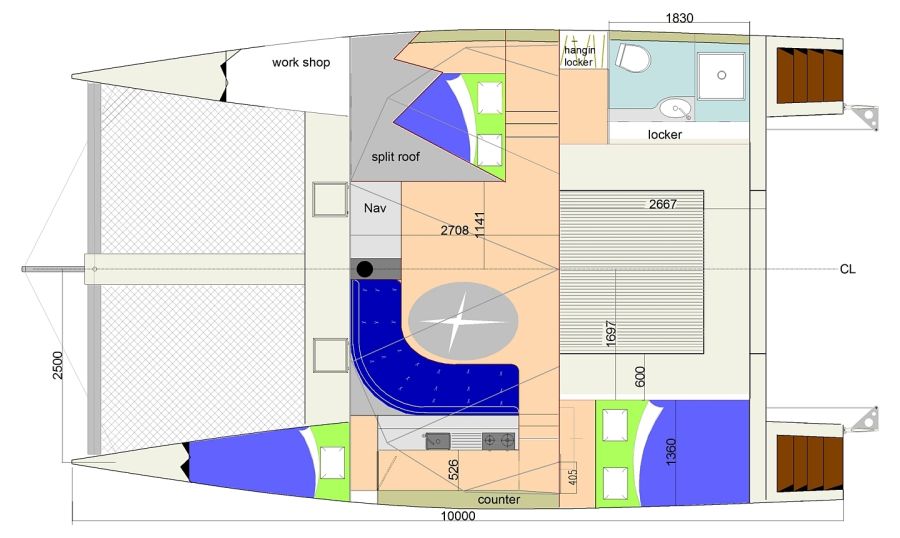

I think the layout speaks for it self. The master berth room is at the place with the lowest movement. It is a sort of split level design. The feeling on the saloon implies a much bigger boat with a full view from side to side over the roof of the master berth room. The kitchen in the port hull has also a lower movement as a kitchen on the bridge deck. So working in the kitchen is more safe to. Personal I the detest the usual kitchen in the saloon. You will find no bigger bathroom in any other design of this size. The clear split from living area, kitchen and bathroom ensures a pleasant stay on the boat also for a long time. The enclosed cockpit enhances the safety on board and will be special appreciated with small children on board. The of center dagger board rudders make room for steps to the water surface. The center mounted board is an other safety feature. The draft of the boat fully loaded is only 0,40m! So you can enter coves no other boat of this size can reach.

In a self build boat, the rig will cost more as the material of the whole boat. My solution will help to get these costs significant down. As mast a glass fiber flag pole is used as base. In combination with the vertical furler without a profile the cost will split in half. I use a double sided sprit as boom (wishbone). In this way, the main sail can be set lower which brings the center of pressure down to. This makes the boat a lot more stable. The jib is a self tending jib and genoa (or flat cut genacker) is equipped with a furler. Again without a profile. The main and genoa have a sleeve which can be opened with a zipper. We used zippers on our PELICAN for 11 years without any problems. This will not only keep the weight down but also the costs.

The boat will be very fast the speed prediction shows for instance a speed of 10 knots in wind force 4. The boat can reach a speed of above 20 knots, which is not interesting for a family boat anyway. The study plans show the speed prediction as a graphical as well as the dynamic stability. The windage of the boat is a lot lower as comparable catamarans. So sailing to windward, also with shortened sails, will be a lot better. This is the reason why I advise to use only two 10 HP outboard engines as auxiliary drives. No smelly and expensive inboard engines!

Interested! For the begin order a study plan (study plan costs are refunded when the plan is ordered), with an example drawing, speed prediction and dynamic stability diagram for different wind speeds. The list of drawings (35) and a list of materials, so you can calculate the costs for the materials.

In a self build boat, the rig will cost more as the material of the whole boat. My solution will help to get these costs significant down. As mast a glass fiber flag pole is used as base. In combination with the vertical furler without a profile the cost will split in half. I use a double sided sprit as boom (wishbone). In this way, the main sail can be set lower which brings the center of pressure down to. This makes the boat a lot more stable. The jib is a self tending jib and genoa (or flat cut genacker) is equipped with a furler. Again without a profile. The main and genoa have a sleeve which can be opened with a zipper. We used zippers on our PELICAN for 11 years without any problems. This will not only keep the weight down but also the costs.

The boat will be very fast the speed prediction shows for instance a speed of 10 knots in wind force 4. The boat can reach a speed of above 20 knots, which is not interesting for a family boat anyway. The study plans show the speed prediction as a graphical as well as the dynamic stability. The windage of the boat is a lot lower as comparable catamarans. So sailing to windward, also with shortened sails, will be a lot better. This is the reason why I advise to use only two 10 HP outboard engines as auxiliary drives. No smelly and expensive inboard engines!

Interested! For the begin order a study plan (study plan costs are refunded when the plan is ordered), with an example drawing, speed prediction and dynamic stability diagram for different wind speeds. The list of drawings (35) and a list of materials, so you can calculate the costs for the materials.

Study plan

18 pages, 15 drawings and pictures, description, list of materials, list of drawings.

US $ 20,00

18 pages, 15 drawings and pictures, description, list of materials, list of drawings.

US $ 20,00

Plans

The plans are delivered as E-book with building instruction and 36 drawings DXF format plans cost:

US $ 1700,-

The plans are delivered as E-book with building instruction and 36 drawings DXF format plans cost:

US $ 1700,-

KD1000 Brazil

editCopyright © 2025 by B. Kohler, K-designs All rights reserved