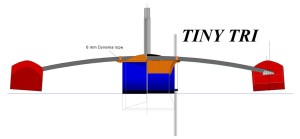

Here is my smallest multi hull in my portfolio. But this little practical trimaran is worth to have his own presentation.

I presume that this is the most easy to build trimaran on the marked.

Cost-wise also on your bank account.

For these goals I incorporated, again, many new ideas, like the rotating mast with stays. The Amas work like water-skies and generate dynamic lift at speed, like foils but without the hassle of foils. The added bodies with some volume have static righting moment.

The Vaka is an easy to build sharpie-shaped hull. More or less an instant build. No stitch and glue. Stitch and glue needs to many work steps, Building on stringers is straight forward operation. The Vaka is 4m long, total weight is 65 kg, So roof rack transport is permitted in most countries of the world.

I presume that this is the most easy to build trimaran on the marked.

Cost-wise also on your bank account.

For these goals I incorporated, again, many new ideas, like the rotating mast with stays. The Amas work like water-skies and generate dynamic lift at speed, like foils but without the hassle of foils. The added bodies with some volume have static righting moment.

The Vaka is an easy to build sharpie-shaped hull. More or less an instant build. No stitch and glue. Stitch and glue needs to many work steps, Building on stringers is straight forward operation. The Vaka is 4m long, total weight is 65 kg, So roof rack transport is permitted in most countries of the world.

PLANS COST

US $ 60,-

US $ 60,-

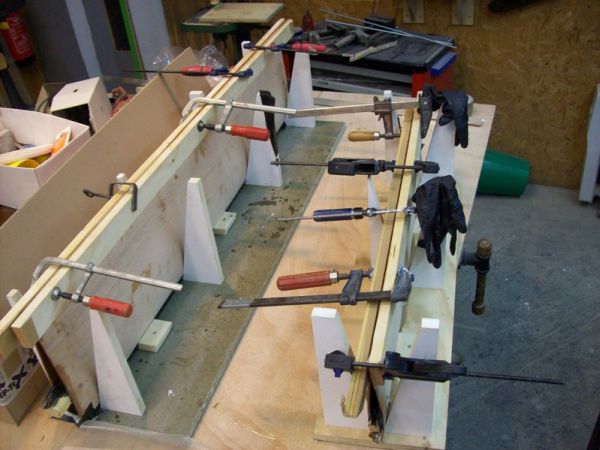

Vaca under construction

The Tiny Tri rig on Matts

tri. An Alaska trail contender

tri. An Alaska trail contender

The Amas are a sort of water ski with some volume. A bit more resistance when slow, at speed better as normal Amas

Dagger board and rudder under construction. We use this hollow board system for all my designs

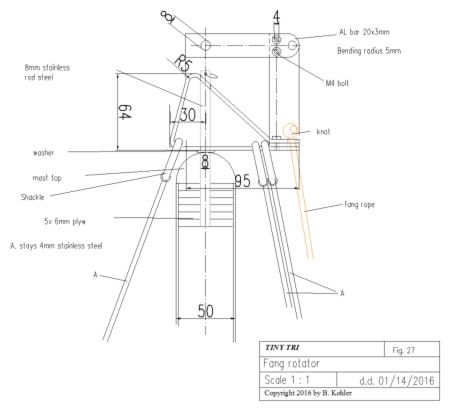

Topmast rotor. This design enables stays and roll mast reeving

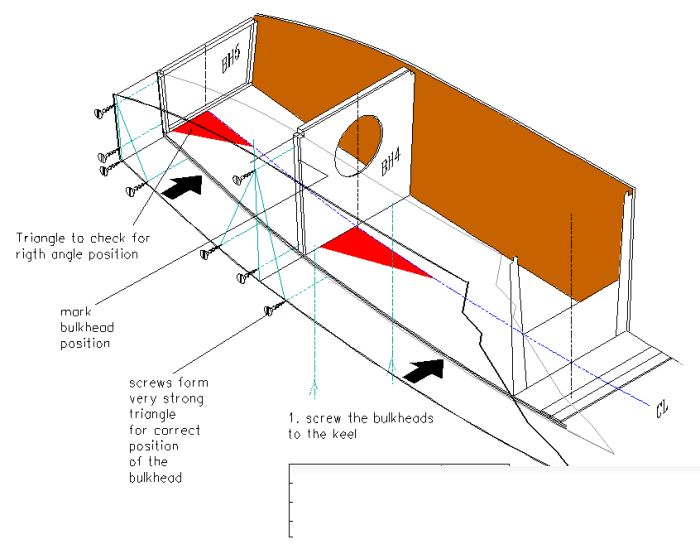

I use for some of my designs a derivative from the aircraft Aluminium construction technique. Called matched hole technique.

You start with some precisely drilled holes, instead of Clegos we use screws. Because it is a flat-bottom boat, the hull can build on a workbench the floor and so one. Whit two big triangles the bulkheads can be set to the correct angle. The whole bottom side "planking bulkheads are pre-fastened with screws. To glue the construction together remove the screws partly. Start with the side planking apply Epoxy and screw all bulkheads to side planking, after curing, do the other side. Now the other side planking is done. Do next the deck parts, finish with the bottom. The deck and keel stringers are first mounted glued to the side panels. There are sufficient gluing areas. The construction can be finished now. No drilling precise holes to the parts. No applying wire to mound pieces together. No fiddling with Epoxy and glass cloth between the holes. And so one. This construction system takes half the time from wiring.

You start with some precisely drilled holes, instead of Clegos we use screws. Because it is a flat-bottom boat, the hull can build on a workbench the floor and so one. Whit two big triangles the bulkheads can be set to the correct angle. The whole bottom side "planking bulkheads are pre-fastened with screws. To glue the construction together remove the screws partly. Start with the side planking apply Epoxy and screw all bulkheads to side planking, after curing, do the other side. Now the other side planking is done. Do next the deck parts, finish with the bottom. The deck and keel stringers are first mounted glued to the side panels. There are sufficient gluing areas. The construction can be finished now. No drilling precise holes to the parts. No applying wire to mound pieces together. No fiddling with Epoxy and glass cloth between the holes. And so one. This construction system takes half the time from wiring.

BILL OF MATERIALS,

DELIVERY CONSIGNMENT

DELIVERY CONSIGNMENT

DATA: Length 4m / beam 2,40m / total weight 65 kg / sail area 9 m2,